Douce-Hydro is committed to providing you with products of impeccable quality, thanks to a rigorous and comprehensive qualified control system. Our aim: to guarantee you reliable, long-lasting hydraulic solutions that meet the most exacting requirements.

Our strengths in quality control:

- Dimensional and geometric control :

- Check all component dimensions using precise measuring tools;

- Check component geometry to ensure optimum operation.

- Checking welds :

- Visual inspection of welds by certified technicians;

- Dye penetrant inspection or radiography to guarantee weld quality.

- Control of surface treatments :

- Checking the thickness and adhesion of surface treatments;

- Controlling the corrosion resistance of surface treatments ;

- Assessment of salt spray corrosion performance (600l capacity).

Hydraulic and functional tests :

- Low-pressure static and dynamic pressure testing to guarantee component resistance;

- Fatigue test to simulate real-life conditions;

- Function test to check that products are working properly.

- Strict safety procedures:

- Compliance with current standards and regulations;

- Use of test equipment.

Thanks to these procedures and this traceability system, we can guarantee :

- Safe, reliable products that meet the highest standards;

- Complete traceability of your products, from raw material to finished product;

- Peace of mind knowing your products are in good hands.

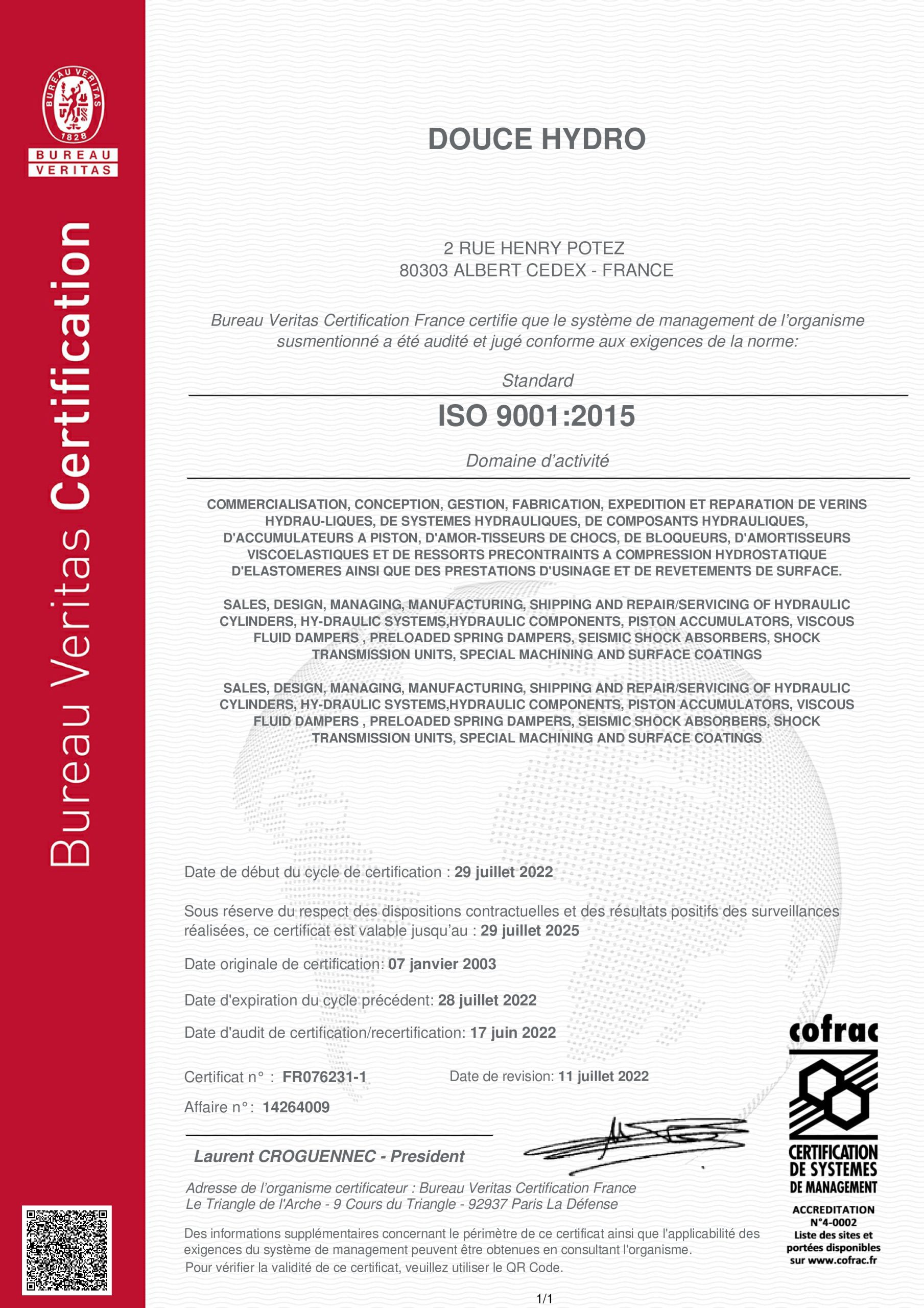

Quality certificates:

ISO 9001 certification for all our activities;

Sector-specific certifications

Comprehensive testing:

Low-pressure static and dynamic pressure testing.

Fatigue test.

Non-destructive testing.

Simulation bench for viscoelastic dampers.

Custom testing to customer specifications.

An electronic curve tracer for precise analysis of test results;

Fluid cleanliness to the highest standards;

Certified welders to guarantee weld quality;

An air-conditioned metrology room for accurate and reliable measurements;

High-performance test benches to test products under real-life conditions;

A test bench with a capacity of 8,000 liters, a flow rate of 470 liters/min. and a power of 50 kW for testing products with different types of oil;

Collaboration with recognized control bodies;

Lifetime traceability of all our products’ technical files since 1950.