Coatings at Douce-Hydro

At Douce-Hydro, surface treatment is based on a rigorous process that is entirely controlled in-house, guaranteeing the quality, durability and optimum performance of metal parts, particularly hydraulic cylinders, the company’s specialty. This autonomy enables meticulous quality control at every stage, reinforcing Douce-Hydro’s commitment to excellence and customer satisfaction.

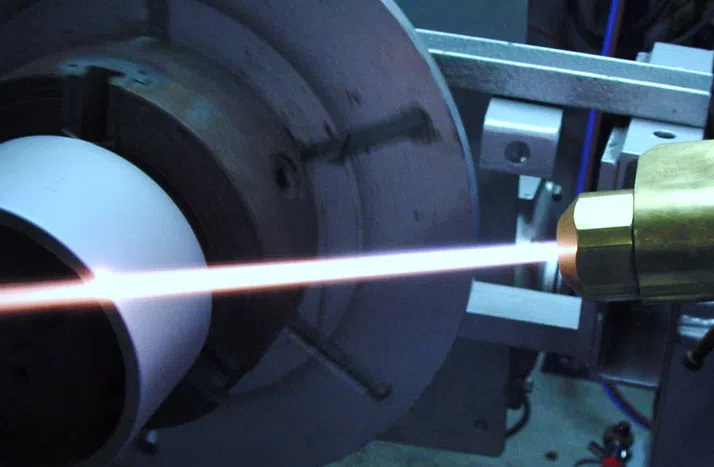

The company’s expertise is based on innovative surface treatment techniques, developed by its R&D department since the 1990s. These include Keradouce®, a nickel- and chrome-free coating that protects cylinder rods against corrosion and abrasion, and Lasertek®, a welded coating process that improves cylinder resistance in extreme conditions. This know-how guarantees solutions tailored to the specific features of each hydraulic cylinder, meeting the requirements of the most demanding industrial applications.

Cleaning and preparation

The first step involves careful cleaning of the parts to remove any traces of oil, grease or dirt. This step is crucial to ensure the adhesion of the coatings.

Stripping

Pickling removes oxides and other impurities from certain metals. It is a preparatory operation, prior to treatment.

Heat treatment application

Some metal parts benefit from heat treatment to improve their strength and durability. This process involves heating the part to controlled temperatures in order to modify its physical properties.

Coating application

Depending on requirements, various coatings can be applied, such as paint, zinc plating or anodizing, to improve resistance to corrosion and weathering.

Hardness

Our internal rod finishing processes provide the hardness needed to guarantee cylinder life in the face of abrasion problems.

Each of these stages is subject to rigorous quality controls to guarantee compliance with the very strict standards applied by Douce-Hydro. Visual inspections and strength tests are an integral part of this procedure.

| HV hardness | Salt spray resistance ASTM B287 | Corrosion resistance | Chemical resistance | Abrasion resistance | |

|---|---|---|---|---|---|

| Metaltek ® | 1000-1100 HV | 1 100h | + | + | + |

| Keradouce ® | 900 HV | 3 000h | +++ | +++ | +++ |

| Lasertek ® 400U | 400 HV | 40 000h | ++++ | ++ | – |

| Lasertek ® 1000U | 1000 HV | 40 000h | ++++ | ++ | ++ |

| Lasertek ® 400I | 400 HV | 40 000h | ++++ | ++ | – |

| Lasertek ® 1000I | 1000 HV | 40 000h | ++++ | ++ | ++ |

Prevent corrosion and abrasion

Each metal part can be subjected to different conditions of use. This premise leads Douce-Hydro to create customized surface treatments based on the customer’s specific needs: this tailor-made approach guarantees protection adapted to each application.