The SMIK sensor is mounted on the cylinder head, and requires special machining and KERADOUCE® coating on the rod. It enables the position of the rod to be determined with the utmost precision and reliability.

Operating principle :

The sensor can only be used on KERADOUCE®.

The KERADOUCE® coating has been developed to offer better corrosion resistance and mechanical properties than the chrome or nickel-chromium coatings generally used.

But we discovered that we could use it for other applications while retaining its original function.

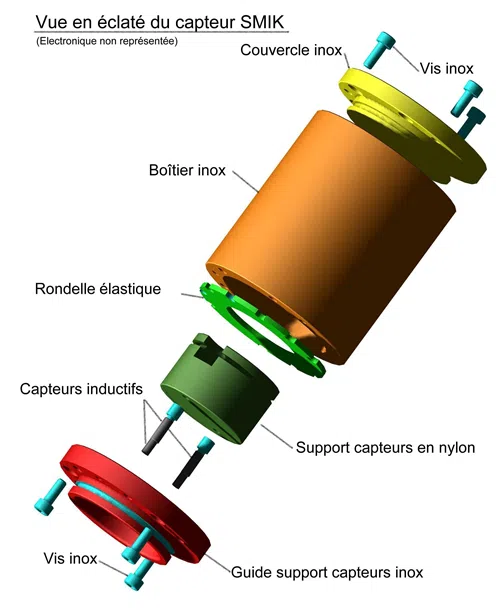

The sensor is equipped with 2 inductive detectors which locate a profile machined under the KERADOUCE® coating.

An electronic board integrated into the sensor processes the signal from the inductive detectors, so that it can be used on any type of system (counting card, PLC, PC……. compatible), enabling us to visualize the position of the rod.

The 2 inductive sensors are mounted on a nylon part which, via an elastic washer, can oscillate perpendicularly to the cylinder axis, thus compensating for the rod guide play.

The advantage of this system is that it has virtually no contact with the stem, guaranteeing maximum reliability. What’s more, there are no sealing problems, as it is not in contact with the pressurized fluid.

The case is made of stainless steel for maximum corrosion resistance.

DIMENSIONS

This sensor has the advantage of being very small in relation to its capabilities.

In fact, the whole unit fits into a cylinder with a diameter of 98 mm and a height of 152 mm.

As we usually mount it on large cylinders, you can’t even see it – it’s totally integrated into the cylinder.

GENERAL CHARACTERISTICS

- General terms and conditions

Operating temperatures: -25°C<T°<+80°C

Humidity: <90%

Environment: marine atmosphere

Travel speed: <2 m/s (10 m/s optional)

Cylinder stroke: < 20 meters

Protection class: IP 68

- Sensor features

Accuracy: ±1 mm (± 0.5 mm optional)

Linearity: <1 mm

Hysteresis: ± 0.05 mm

Temperature: ± 0.025 mm/°C

Supply voltage: 20 to 30 Vdc

Shock resistance: 100 G/6 ms to IEC

Vibration resistance: 10 G/100 Hz to IEC

Disturbance immunity: IEC 1000-4-2 Severity grade 3, IEC 1000-4-3 Severity grade 3, IEC 1000-4-4 Severity grade 3, IEC 1000-4-6 Severity grade 4

- Initialization

Initialization is carried out in our workshops, depending on the precision required and the type of profile being machined.

On the other hand, we recommend connecting the sensor to limit switches, in order to reset the limit switch values and avoid accumulating errors should the sensor accidentally lose information (micro-cuts in the power supply or jolts when the rod is extended beyond the sensor’s speed limits).