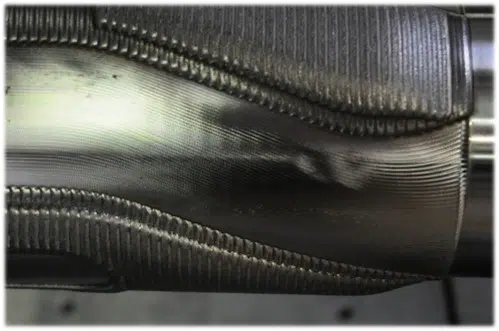

LASERTEK® is a welded coating process applied to cylinder rods to prevent wear and corrosion in extreme environments.

The final coating is a durable, corrosion-resistant layer whose characteristics offer a high degree of resistance to extremely high contact forces (radial forces) and bending forces (rod bending).

What’s more, LASERTEK® coatings meet the qualification requirements of the DNV® standard.

The technology has been developed by Douce-Hydro’s R&D department since 2010.

Can be supplied by Douce-Hydro

LASERTEK® is the result of a combination of materials, process and parameters.

With its 30 years of experience, Douce Hydro has developed the machine’s parameters and settings to optimize the final results.

The process is subject to maximum control thanks to the qualifications and internal controls carried out.

The powders themselves are subject to special controls, monitoring and traceability.

In laser cladding, the laser beam is defocused onto the workpiece with a selected spot size.

The powdered filler material is transported by an inert gas through a nozzle into the melt bath.

Laser optics and molten powder are moved over the surface of the part to be treated to deposit single beads, complete beads or even multi-layers.

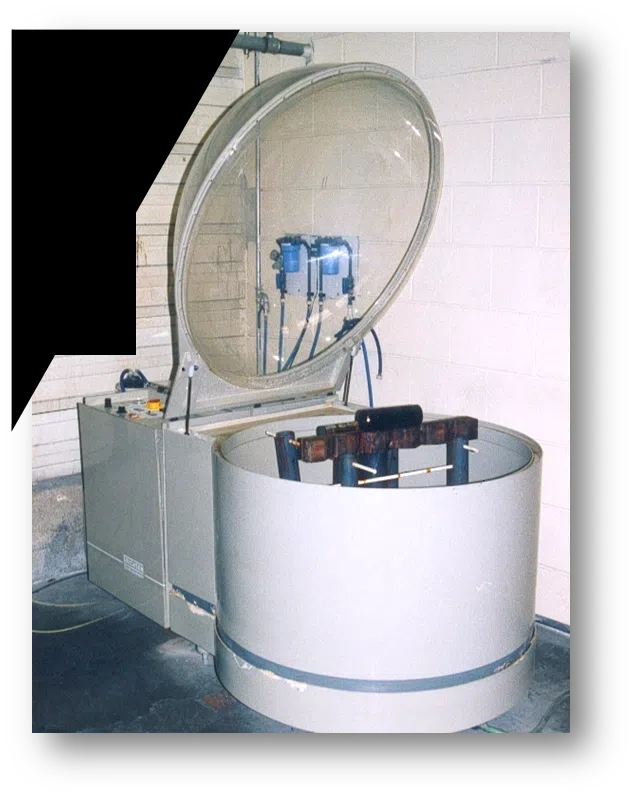

Acetic Salt Spray Test Equipment

This test is carried out in accordance with NF ISO 9227 (ASTM B 287) .

Enclosure: cylindric of 1000 l (ERICHSEN Model 606 – 1000L)

Features of the salt solution :

- [NaCl] = 5% in demineralized water.

- pH = 3.2 ± 0.1 added with CH3COOH.

- rainfall: 1.5 ± 0.1 ml/h/80 cm².

- Density = 1.035 ± 0.005.

- Temperature: 35°C ± 2°C.

- Air pressure: 1 bar ± 0.2 bar (= 14.5 psi ± 2.9 psi)

- Sample position: placed horizontally on two plastic bars.

- Sample preparation: ends protected with grease and coating degreased with acetone.

The test stops when a trace of corrosion appears; the duration of the test is read on the counter.