The hydraulic cylinder is a central part of a hydraulic system. The slightest failure, however minor, can partially or totally compromise a machine’s performance and expose its users to dangerous situations. Specialized in the design and manufacture of hydraulic cylinders, Douce-Hydro also handles their maintenance: in the event of an anomaly, we offer a repair service that will quickly secure your hydraulic system and enable it to return to full performance.

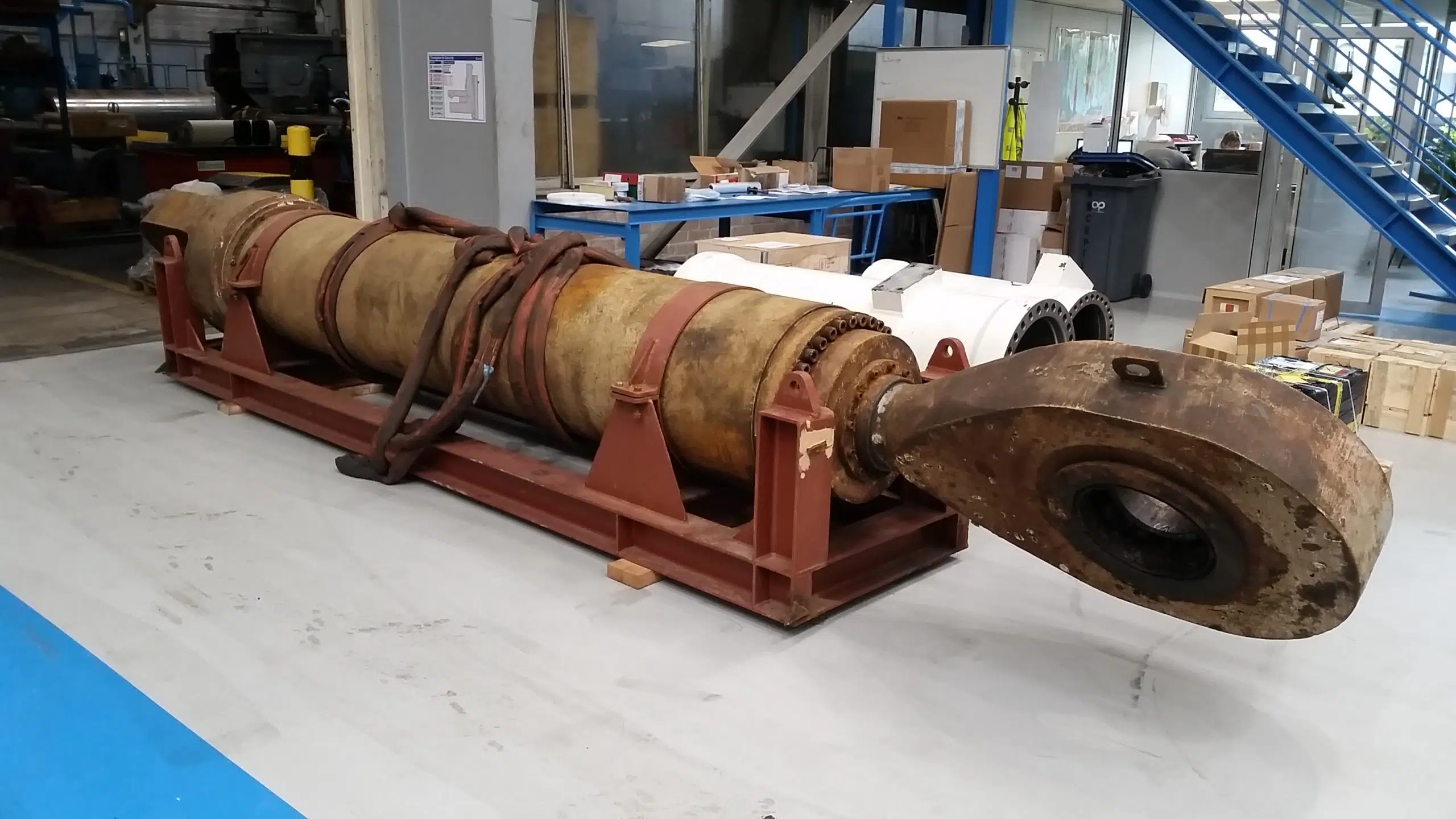

Cylinder disassembly for overhaul

The repair of a hydraulic cylinder usually begins with a thorough dismantling process. This step enables us to establish an initial diagnosis and identify any problems specific to the cylinder. Douce-Hydro technicians inspect every part, from the rod to the seals, to determine the cause of the failure. In many cases, problems are caused by worn seals or damage to the cylinder rod.

Once the problem has been identified, Douce-Hydro will repair it: if the failure is irreversible due to wear or severe damage to the cylinder, our teams will replace the parts that have become inoperative.

When it comes to repairing or servicing very old hydraulic cylinders, or those designed for very specific applications, it is sometimes essential to produce customized components.

Douce-Hydro, renowned for its ability to manufacture “customized” products, whether originally made by us or not, is able to restore old or unique cylinders.

Why choose Douce-Hydro for hydraulic cylinder repairs?

Choosing Douce-Hydro for the repair of hydraulic cylinders is a choice that offers several guarantees. The company’s specialization in the design and manufacture of hydraulic solutions, backed by decades of experience, enables us to service and repair cylinders of all sizes, including the most complex models.

Our know-how in precision machining, our strong team of experts, our cutting-edge technical resources and the use of high-quality, custom-made parts guarantee a long-lasting, reliable repair.

Retrofitting a hydraulic cylinder

Douce-Hydro also offers a retrofit service, designed to modernize or improve the performance of existing hydraulic cylinders. This option is often more economical than complete replacement, and considerably extends the cylinder’s service life.

Retrofitting can involve a number of modifications designed to increase the cylinder’s efficiency, safety and functionality: for example, replacing worn parts, integrating new technologies or updating components.

Retrofitting a hydraulic cylinder usually begins with a complete diagnosis of the cylinder to identify components requiring renovation or upgrading. Replacing seals, repairing or changing the rod, updating sensor systems or improving control systems are just some of the measures implemented as part of a hydraulic cylinder retrofit. Adjusting dimensions or specifications are other ways of adapting a hydraulic cylinder to new operational or regulatory requirements.

Proper maintenance of hydraulic cylinders

Regular maintenance of hydraulic cylinders is essential to prevent breakdowns and extend their service life. This means regularly checking the condition of seals and cylinder rods, and keeping the hydraulic fluid clean. Well-maintained cylinders require fewer repairs and perform better over time.

Douce-Hydro recommends proactive maintenance to avoid unexpected and costly breakdowns. The company offers regular maintenance services to keep your hydraulic cylinders running at peak performance over the long term.