The piston accumulator is a device used to store energy in the form of pressurized fluid. Its role is to maintain the operating rhythm of a hydraulic system affected by an internal leak, or to temporarily boost power in the event of a peak load.

What is a piston accumulator?

A piston accumulator is a device capable of storing energy and then returning it to the circuit to which it is connected.

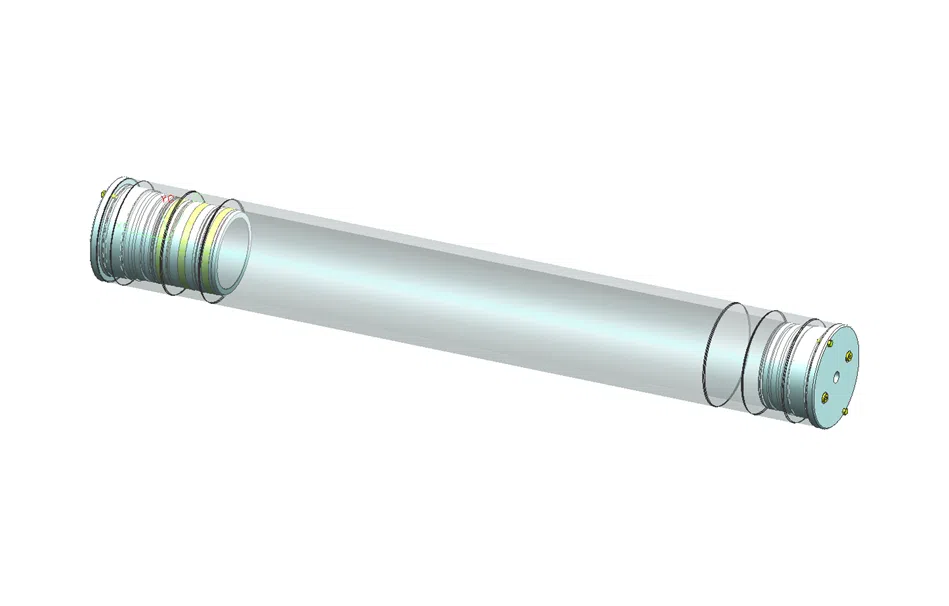

Piston accumulators are hydropneumatic devices comprising two compartments separated by a piston which acts as a leaktight separator.

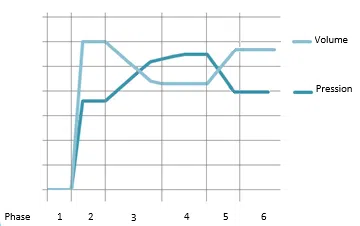

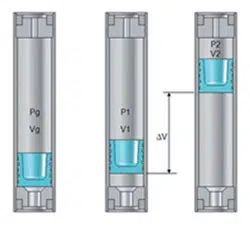

Each time the accumulator is used, there is a change in the state of the gas it contains. The operating principle of the hydropneumatic accumulator can be described using the gas’s compression and expansion characteristics.

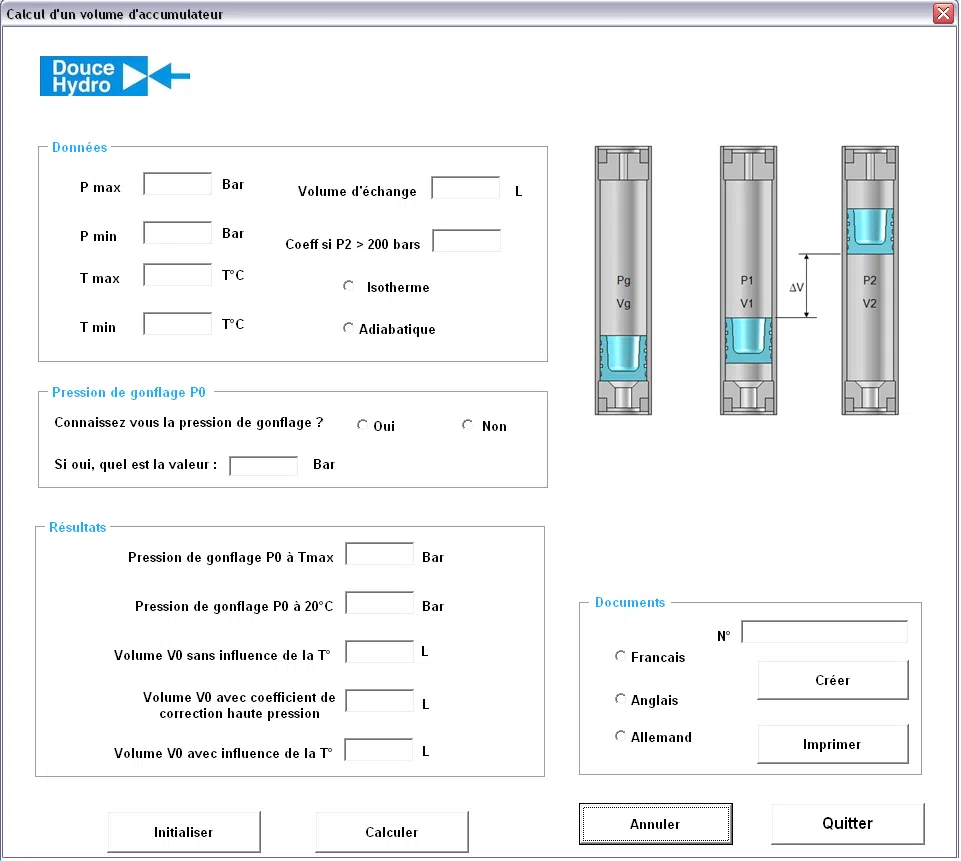

The relationship between pressure and volume is governed by BOYLE-MARIOTTE‘s law. Depending on the speed of the change of state, the transformation will be ISOTHERMAL, ADIABATIC or POLYTROPIC.

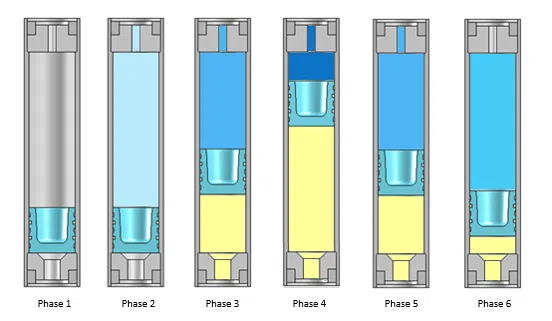

Phase 1 = The accumulator is empty on the liquid side and unpressurized on the gas side.

Phase 2 = The accumulator is pre-charged with gas at design pressure Pg.

Stage 3 = The hydraulic system is pressurized. System pressure exceeds precharge pressure Pg.

Stage 4 = The hydraulic circuit reaches its pressure peak. The accumulator fills up to its design capacity.

Stage 5 = Pressure drop in the circuit. The pre-charged gas evacuates the accumulator liquid into the circuit.

Stage 6 = Minimum pressure is reached, the accumulator has returned its maximum volume of liquid to the circuit.

Characteristics of Douce-Hydro piston accumulators

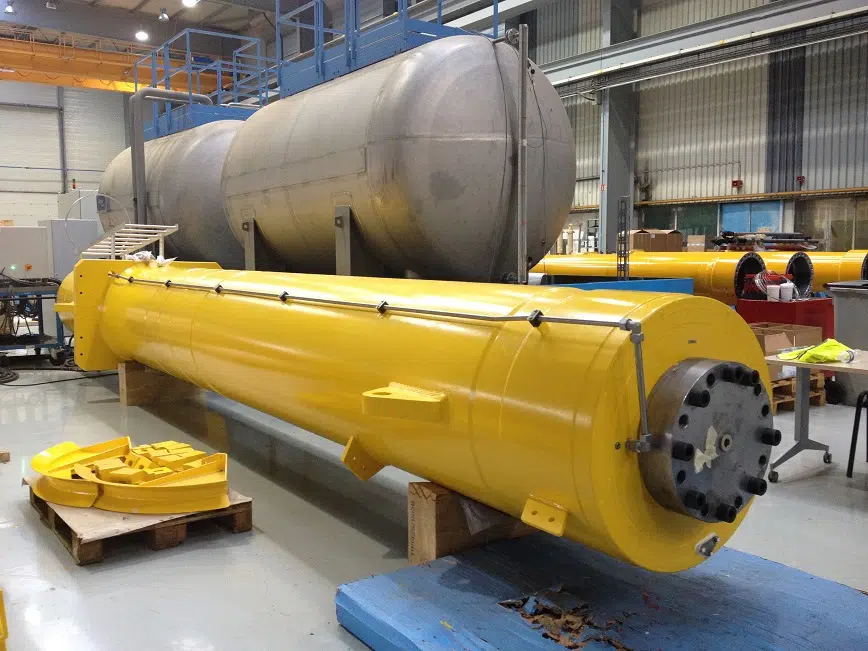

Thanks to the industrial resources at our disposal, Douce Hydro is able to offer piston accumulators of all sizes.

Compression ratio :

The volume of oil an accumulator can store depends on the amount of compression it can withstand.

If required, the piston accumulator has a better compression ratio than bladder or diaphragm accumulators.

Reliable :

In a piston accumulator, the piston separates the fluid from the gas, with no intercommunication between gas and fluid.

In applications where the accumulator has to remain pressurized for long periods (for emergency energy reserves), a bladder accumulator leaks slowly, up to 10% of the pre-charged gas, necessitating periodic maintenance of the inflation pressure or replacement of the bladder itself.

Storage :

Keeping a bladder or diaphragm accumulator out of operation for a long time causes deterioration of the rubber.

Keeping a piston accumulator out of operation for a long period of time has no harmful effects, provided the pre-charged gas contains no moisture, as this would corrode the cylinder interior.

The interior of Douce Hydro piston accumulator cylinders can be given an anti-corrosion coating to overcome this problem.

Volumetric performance :

An accumulator is charged with a volume of oil, and we assume that this volume of oil is the volumetric performance.

To restore this volume, an accumulator must have no dead space.

In a piston accumulator, when discharging, the piston may come up against the oil outlet orifice.

In a bladder accumulator, when discharging, the bladder may come up against the oil outlet orifice, thus obstructing it. What’s more, the bladder may become deformed and therefore deteriorate, which is why manufacturers recommend that the volume to be restored should not exceed 0.9 x the total accumulator volume.

The piston accumulator therefore offers better volumetric performance.

Operating position :

For a piston accumulator, there are no constraints in terms of operating position.

The piston of a Douce Hydro piston accumulator will always have the same performance, but the same cannot be said for bladder accumulators, which depend on the flexible movement of their bladder and on gravity to restore the stored volume. Poor positioning of a bladder accumulator results in uneven distribution of forces and therefore deterioration of the rubber bladder.

Safety :

The assurance that an accumulator offers during operation is essentially based on its functionality and the simplicity of its execution, so it’s important to carry out stringent, effective and precise quality controls. The most important elements of a piston accumulator in terms of functionality are its ground cylinder and sealed piston.

What’s more, Douce Hydro piston accumulators offer maximum safety because they are designed and produced to the most stringent quality standards.

Whereas with the diaphragm accumulator, apart from the mechanical components, the most critical point remains the rubber diaphragm, which is obtained by plastic injection molding. When dimensions exceed a certain limit, it becomes very difficult to control the quality of composition, strength, imperfection and thickness. A problem with the diaphragm or bladder can lead to blockage of the hydraulic circuit to which it is connected.

It’s important to note that if a battery were to fail, it would happen gradually.

Capacity :

With the above-mentioned difficulties in obtaining a completely homogeneous bladder, without imperfections when dimensions exceed a certain limit, bladder accumulators are only used for low capacities, the maximum limit being 50 liters. For piston accumulators, there is no limit.

Control :

With a piston accumulator, it’s easy to control the position of the piston. Knowing the position of the piston, it’s quite simple to know the volume of liquid remaining in the accumulator, and the analog or digital signal sent by the sensor can be used by the control unit to control a pump, or to provide feedback on information or anomalies.

Maintenance :

The service life of a piston accumulator is determined by its seals, which need to be replaced only when they lose their efficiency, at a modest cost.

What uses for piston accumulators?

When designing bespoke cylinders, the hydraulic pressure level is another parameter to consider: depending on the customer’s specific requirements, Douce-Hydro optimizes the sizing to guarantee optimum performance without altering the performance and durability of the overall hydraulic system.

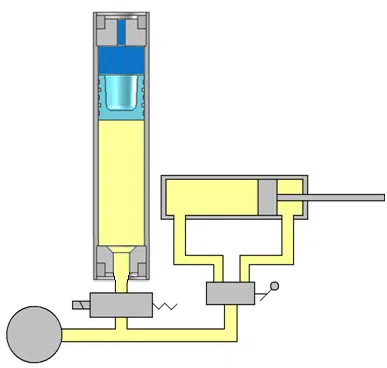

EMERGENCY POWER RESERVE

In a hydraulic circuit, in the event of a drop in pressure, it is sometimes useful to have a reserve of fluid available quickly. Indeed, during certain cycles, it is sometimes necessary to keep actuators in position to ensure the safety of people and installations.

A Douce Hydro piston accumulator installed in a hydraulic circuit provides an immediate reserve of fluid.

When the piston accumulator is used for this function, it must provide rapid discharge, i.e. without heat exchange, and slow recharge, i.e. with heat exchange.

Battery operation is therefore adiabatic during discharge and isothermal during recharge.

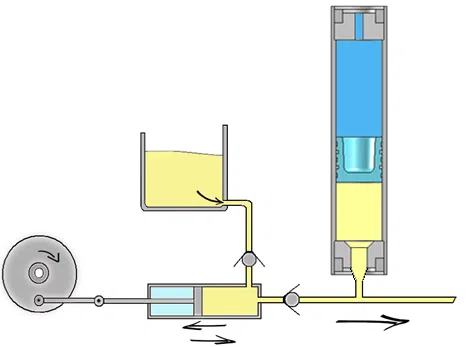

PULSE COMPENSATION

Reciprocating or peristaltic positive-displacement pumps inevitably create pulsating pressure in the circuit due to their instantaneous flow variation. Flow variation = pressure variation = hydraulic pulsation. The use of a piston pulsation damper in the hydraulic circuit, installed as close as possible to the pump, attenuates pulsation, thus reducing vibration and noise and stabilizing flow.

Typical applications, diaphragm pumps, piston pumps, metering pumps, peristaltic pumps and air-operated pumps

When the piston accumulator is used for this function, it must provide rapid discharge and recharging without heat exchange.

The battery therefore operates adiabatically during discharge and recharge.

ANTI-COUP DE BELIER

In a hydraulic circuit, the sudden closure of valves, solenoid valves, etc., or a sudden change in pressure generates kinetic energy in a moving column of fluid.

This phenomenon is more commonly known as water hammer.

A Douce-Hydro accumulator connected to a circuit subject to this phenomenon automatically absorbs the fluid’s kinetic energy.

When the piston accumulator is used for this function, it must provide rapid discharge and recharging without heat exchange.

The battery therefore operates adiabatically during discharge and recharge.

The overpressure ΔP generated in the pipe by the sudden closure of a valve is influenced by the length of the pipe, the flow rate, the density of the fluid and the closing time of the valve.

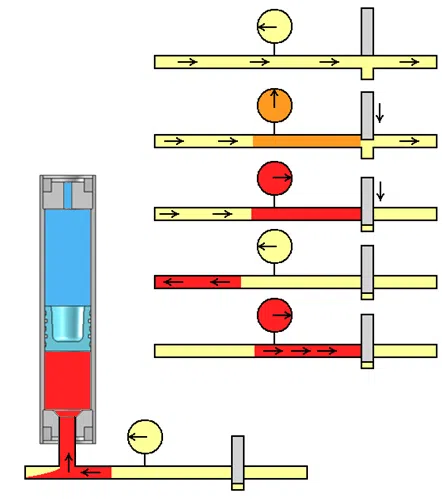

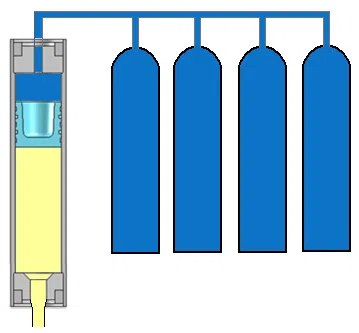

ADDITIONAL BOTTLES

In cases where a considerable quantity of liquid has to be obtained with a small difference between the Pmin and Pmax service pressures, the resulting volume Vgis large compared to the volume to be restored.

The accumulator would therefore have a large volume of gas and a small volume of liquid to release, in which case the piston would work over a small portion of the accumulator’s total length.

When this happens, it’s a good idea to receive the volume of nitrogen in additional gas cylinders.

Accumulator volume is calculated for isothermal or adiabatic transformations, with temperature influence.

SIZING PISTON ACCUMULATORS

For each of these functions, the method for sizing a hydraulic accumulator changes. It is not possible to precisely size a hydraulic accumulator using simple diagrams and formulas.

Douce Hydro has the calculation tools to support and advise you throughout your project.

CERTIFICATION

In the European Community :

Hydraulic piston accumulators are pressure equipment as defined in Directive 97/23/EC. They are closed, non-flammable equipment designed and built to store and release liquid under pressure. The manufacturer of the equipment must guarantee compliance with these regulations.

Directive 97/23/EC came into force on November 29, 1999 and has been applicable since May 29, 2002. This directive applies to the design, manufacture and conformity assessment of pressure vessels placed on the market. It guarantees the free movement of goods within the European Community. Member states of the European Union do not have to prohibit or restrict the marketing of pressure equipment such as piston accumulators, if the equipment complies with the requirements of the directive and bears the CE mark of conformity.

Douce Hydro piston accumulators are designed and manufactured in compliance with Directive 97/23/EC.

They are supplied with a CE certificate of conformity and the CE mark of conformity.

Outside the European Community :

Piston accumulators installed outside the European Community must be supplied with the relevant test certificates required in the country of installation. In this case, the customer must specify this.

Douce Hydro piston accumulators can be supplied with any certificate.

Depending on the country and the foreign authorities, the requirements will differ:

- In Russia, piston accumulators follow the GOST-R, Rostechnadzor permit,

- In China, piston accumulators follow the ML (Ex SQL),

- Rest of the world, piston accumulators follow ASME,

- For shipbuilding, piston accumulators follow BS-L Lloyds register,

- For use on ships, piston accumulators follow RINA.

OPTIONS :

Douce Hydro strives to provide you with the solutions best suited to your needs.

Douce Hydro offers a wide range of options and accessories for this purpose:

- Limit switch detection system,

- Piston position detection system,

- Cylinder lining in chrome or Kanigen to reduce wear on seals and protect against corrosion when using certain fluids.

- Special external protection to your specifications,

- Piston damping when the accumulator is subjected to high restitution speeds and a high number of cycles.

- Safety stop block,

- Fastening elements,

- Nitrogen inflator,

- Inflating accessories,

- Safety features,

- Nitrogen bottles,

- Accumulator Rack PACKAGE: complete supply of accumulator rack with nitrogen cylinders, safety equipment, piping …

- Cylinders + Accumulators PACKAGE : Complete supply of cylinders + accumulators with safety element, piping…